Earlier this summer, Envision Plastics sent out a survey to existing customers that centered around how our No Molds Required (NMR) technology had an effect on their most recent custom plastic enclosure project. No, it wasn’t a customer satisfaction survey - we have all seen enough of those! It was based on value attributes of NMR as whole, what features of their custom enclosure design they liked most, and also what other capabilities they wished we offered so we could fulfill more needs as a one stop shop.

- Cost of Prototype

- Cost of Production

- Quality

- Lead Time

- Design Assistance

- Minimal Upfront Capital Expense

Customers valued a pretty even balance of attributes with respect to their most recent custom plastic enclosure projects. However, the highest ranked attribute was quality. This does not surprise us as we consider quality one of our strengths – with both new projects and repetitive production enclosure projects.

- The fact that we do not use molds or tooling at all – cost savings!

- Digital Printing of logo’s, graphics, and text on plastic enclosures

- Ease of design and flexibility with the design.

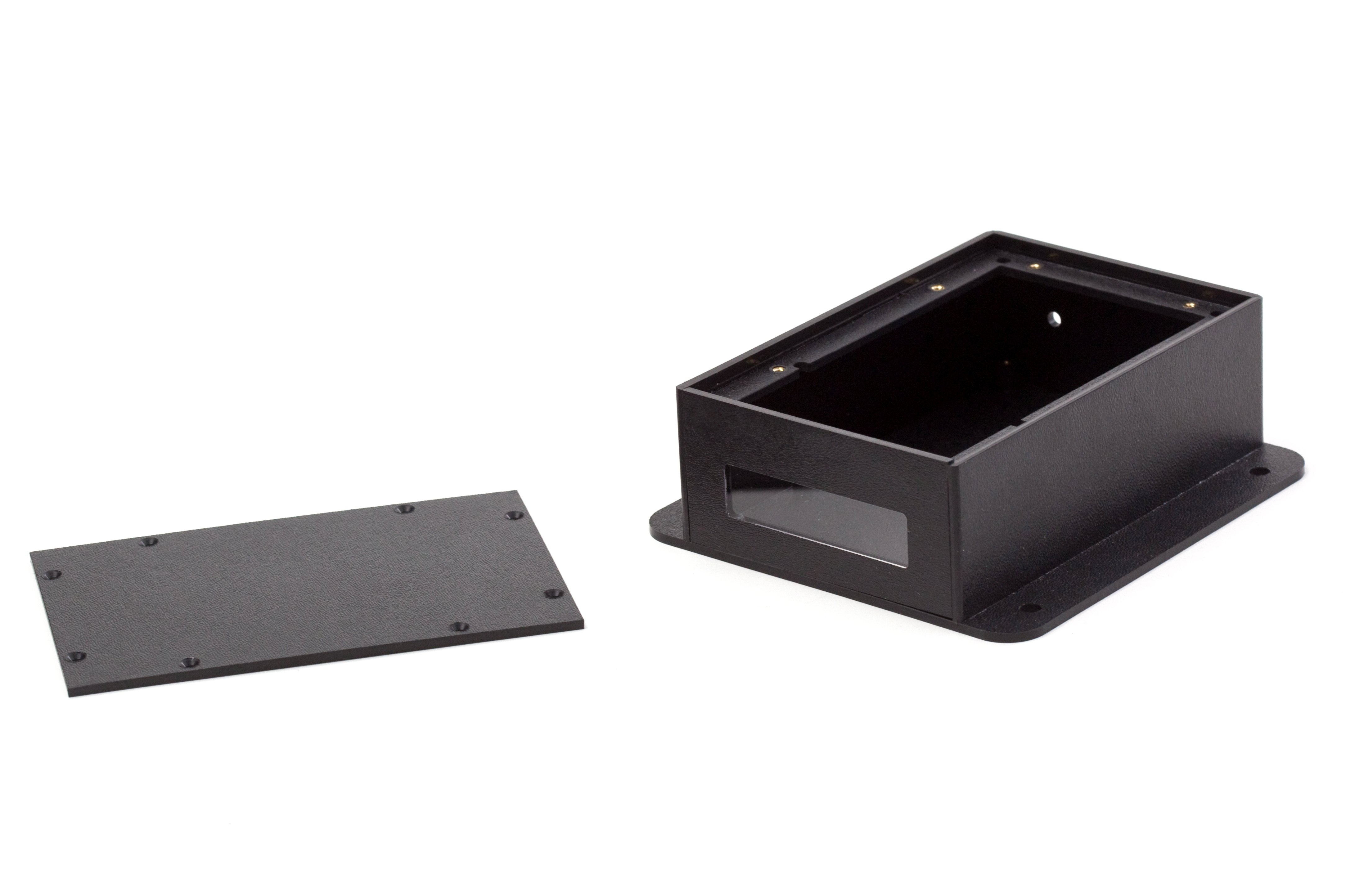

- Use of threaded inserts EXACTLY where they were needed for mounting PCBs.

Overall, the survey provided great insight to things we are doing right at Envision and what our customers value most (or the fact they value it all by the balanced responses!). It is also very positive to see that nearly half of the respondents had an upcoming project they would use us again for. That is what keeps us going and fuels our innovative thinking in continuing to provide a truly unique plastic enclosure manufacturing experience.